This is the 1st part of a multi-part series. View the rest:

- Part 1: Plans and Materials

- Part 2: Racetrack

- Part 3: Vertical Skirt

- Part 4: Subtable and Playing Surface

- Part 5: Finishing It Up

This is the first in a series of posts recording my experience building a solid oak, octagon-shaped poker or game table. It will be written as I work on the table, hopefully all within the next few weeks.

Let me be clear: I am not a professional woodworker. I simply enjoy building things as a hobby, and I try to build things I know I’ll use and love. Since my family and I love board and card games, a table like this is a perfect project for me.

I’ll do my best to provide as much detail as I can throughout the process, and I’ll try to take a lot of photos. With that…

The Plans

Whenever I do a project like this, I always try to work with commonly available wood stock sizes and materials, so it’s cost-effective and easy for someone else to replicate. Keeping that in mind, I tend to draw up plans based around this philosophy.

I also decided to buy the pedestal base and legs already made from a great little company in Tennessee called Adams Wood Products. Building something like that is probably beyond my ability, so for a pretty reasonable price, I just had them ship a set to me. It’ll save me a lot of time and, probably, frustration.

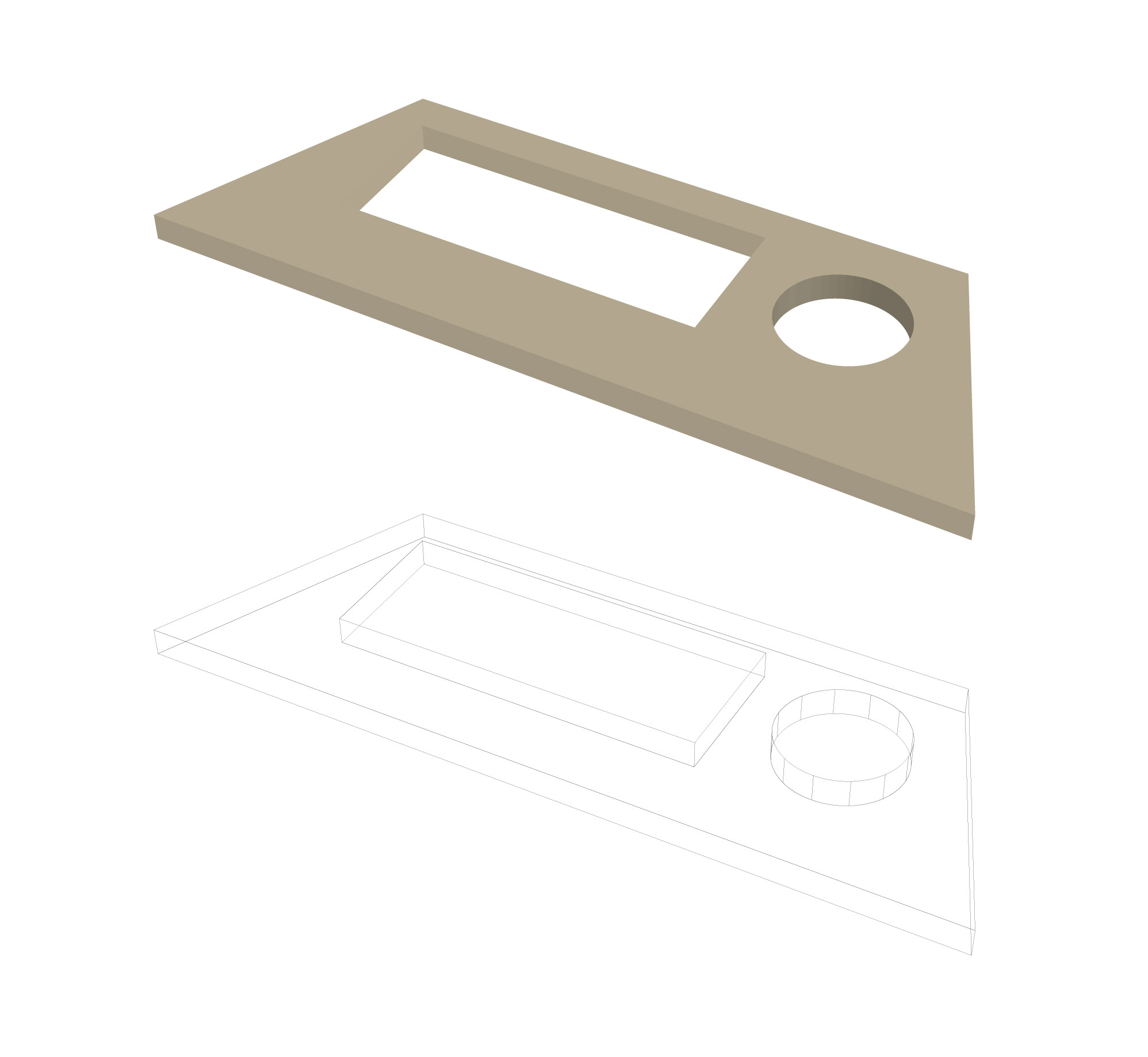

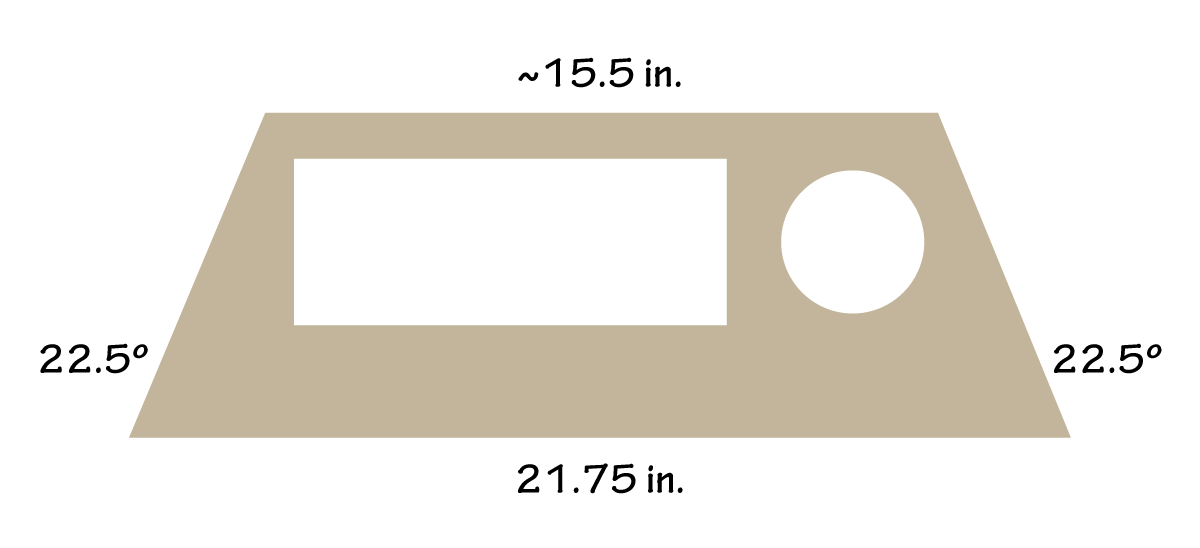

To start, the playing surface will be made up of 8 pieces that each look like this:

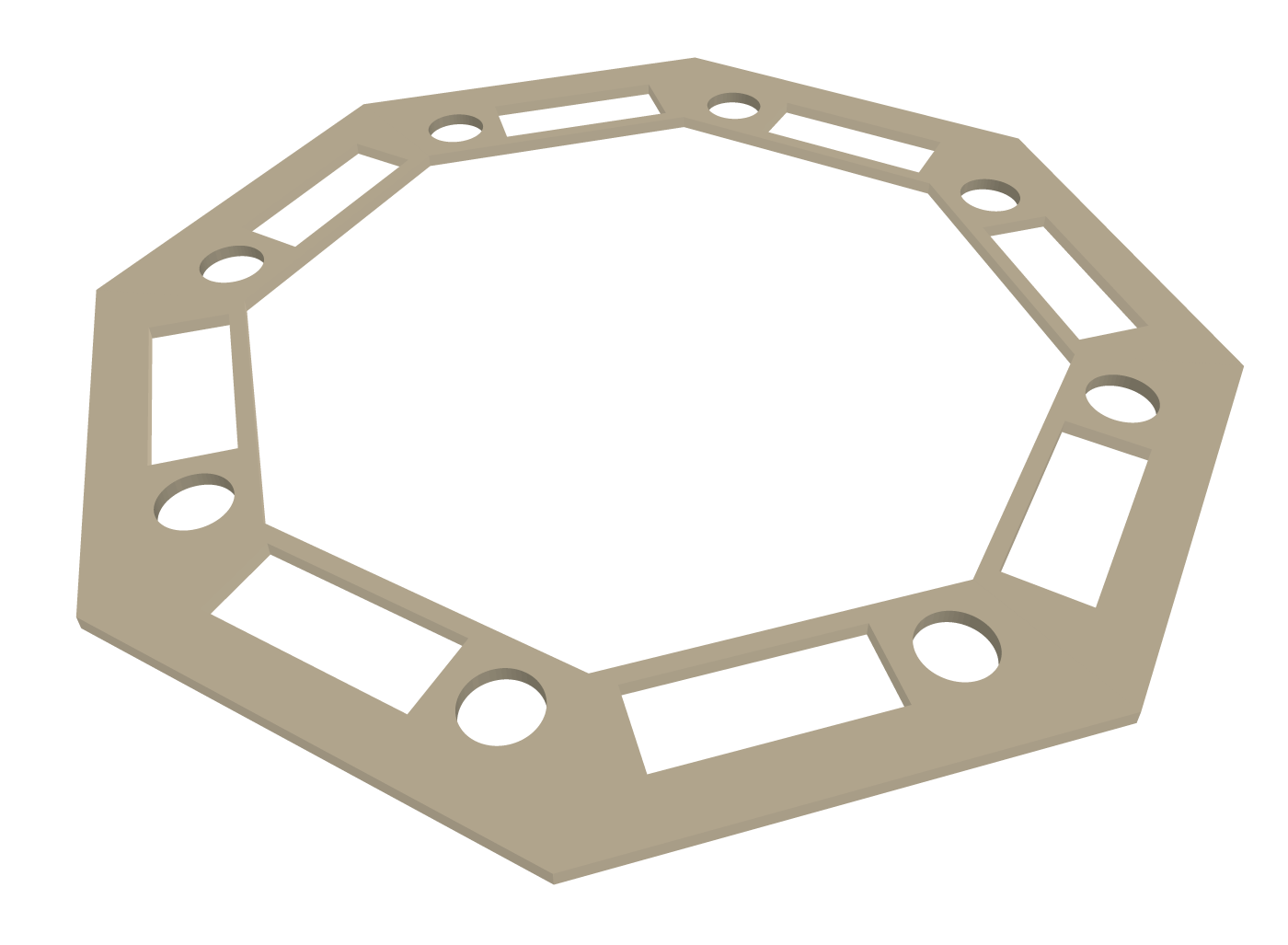

Once you cut out 8 of them and glue them together, the goal is to end up with something like this:

I’ve made some calculations based on using a 4′×4′ piece of plywood as the table base and determined the following measurements:

I’m not sure of the exact dimensions of the chip holder area or the cup holder hole yet, since I haven’t gotten the cup holders in the mail yet. I’ll wait until then to see what size hole I need. Then, I’ll want to match the cup holder width to the width of the chip holder area, just to make it nice and consistent.

Pro Tip: Order your cup holders, felt, etc. in advance. And don’t trust the manufacturer’s measurements on things like cup holder hole size. Wait until you get the materials in and measure it yourself. I bought a hole cutting drill bit based on the size the manufacturer gave and the cup holders didn’t fit! Lesson learned.

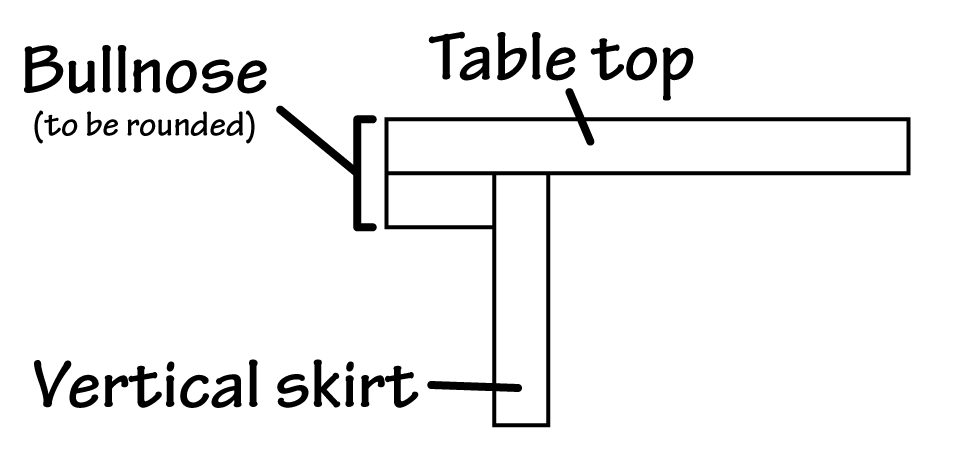

You’ll notice I made the chip holder area closer to the inner edge. The reason for this is that I’ll be adding a bullnose edge and a vertical skirt underneath this layer, so I need a little extra breathing room. Here’s a cross section of what I mean:

This is all I’m going to use for planning purposes, though there’s a lot more going on in my head. I’ll try and expand upon that as I go through the process of the build.

The Materials

Here’s what the final materials list ended up being:

Lumber

- 4 – 1″×8″×4′ Red Oak board (outer table surface)

- 4 – 1″×4″×4′ Red Oak board (vertical skirt)

- 4 – 1″×2″×4′ Red Oak board (bullnose)

- 1 – 1″×12″×2′ Red Oak board (pedestal mount)

- 2 – 4′×4′×1/2″ Red Oak plywood (playing surface and sub-surface)

- 1 – Wood Pedestal

- 4 – Pedestal Legs

Hardware

- 4-pack of adjustable furniture feet

- 10 – 1/4″-20 5/8″ T-Nuts

- 10 – 1/4″-20 3/4″ Bolts

- 1 Quart Stain

- 1 Quart Polyurethane

For the stain, I’m using Minwax English Chestnut for the color. For the polyurethane, I’m using Minwax Fast-Drying Polyurethane in Satin finish.

Felt, Foam, etc.

- 48″×100″ Green Velveteen Fabric

- 48″×48″×1/4″ thick Closed-cell High Density Foam (goes right under the felt)

- 8 – Large Stainless Steel drop-in cup holders

Next Steps: The racetrack

Stay tuned. The next step will cover shaping the 8 pieces for the table top and fitting them together.